Case: Thermomur

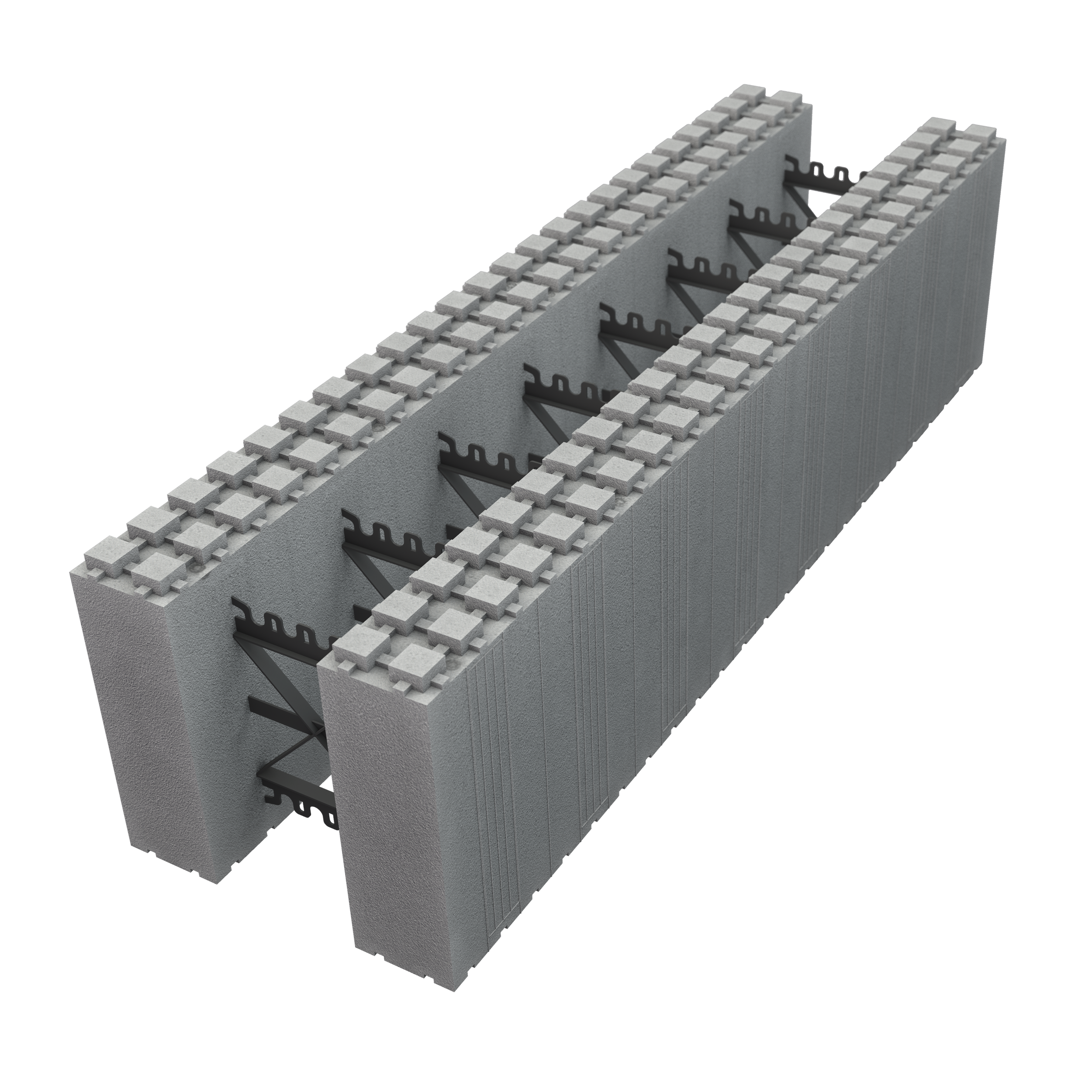

Thermomur 350 Super

Jens Fjeldal (Private builder)

Sustainable Architecture & Construction / Future Materials

On a hillside in Snekkersten, Denmark, a unique building project has taken shape. Designed by architects, the 2-floor villa with an ocean view has been built of Thermomur 350 Super.

The villa is designed with large clear spans and panoramic windows, which a traditional construction would not have supported. The hillside and difficult accessibility on site were also decisive for Jens Fjeldal when choosing to build with Thermomur.

“Access to the building site was difficult, and light building materials were required, in order to move the materials around without using machinery”, says Jens Fjeldal.

The grey Thermomur blocks contain graphite, increasing the insulation capacity by 20% compared to a similar block in white EPS. This gives Jens Fjeldal a well-insulated home meeting the energy requirements of today.

“The blocks are easy to work with, and changes can easily be made during the building process. At a late stage, I wanted to add another window to the 1st floor bathroom. Had I used traditional building materials, it would not have been possible. However, as the outer walls are made of EPS, it was easy to install another window. Furthermore, the solid concrete core means that large clear spans and visible rafters could be installed”, says Jens Fjeldal.

The house is designed by Lars Gitz Architects.

Link:

Carmo supplies 10 tons of surplus plastic material each year to the Swedish bag manufacturer Hinza that transforms the material into designer bags. When Hinza uses the 10 tons of plastic each year, the recycling corresponds to a saving of approximately 22,000 kilos of emitted CO2 compared to if the material had been burned as waste material.

Stolen ”R.U.M” – som står for ReUsed Materials - fås i tre varianter, hvor råmaterialet til stolen enten er plast fra elektronikaffald, fiskenet fundet i havet eller et mix af fiskenet og Carlsbergs ølfustager.

Disposable medical devices from a growing network of Belgian hospitals are turned into aesthetic and long-lasting wall covering for healthcare facilities.

Bug Bite Thing® is made from PE and the product is re-usable. The company provides life-long guarantee which is part of their sustainability vision.

The big challenge in hospitals and clinics all over the world is how to fixate the biopsy in formalin without exposure to spillage or vapour. Formaldehyde is a known human carcinogen which affects health in many nega-tive ways. Either when a person is exposed directly or through inhalation. Long term exposure to formaldehyde has been proven to be associated with an in-creased risk of cancer of the nose, nasopharyngeal and lung cancer.

Droneholdet har udviklet den første ”blended-box wing” drone. med et specielt vingedesign, som er udviklet for at gøre fly mere energieffektive. Konstruktionen af vingerne gør, at flyet bruger mindre energi på at holde sig flyvende.

Offshore wind energy is an important source of renewable energy. Decommissioned Vindeby blades were adopted by Technical University of Denmark, DTU Wind, and are currently used in ongoing project activity investigating the fibre-reinforced composite structures.

Giv nyt liv til dine injektionspenne fra Novo Nordisk, Lilly, Sanofi og Merck. Tag dine brugte penne med på apoteket eller din fertilitetsklinik. Materialerne får herefter nyt liv frem for at ende som affald.

The bio garage set is developed and produced to ensure the future growth of sustainable plastic products with focus on sustainable materials, production, play and learn, recycled to become a new item again. The raw material is renewable and made from residuals of the sugarcane production.

All LifeStraw products start with advanced hollow fiber membrane technology. Picture bundles of straws with microscopic holes in them, so small that organisms like bacteria, parasites, and even dirt and microplastics cannot pass through. Think of a super advanced spaghetti strainer or tea sieve.